14:56 FRABA POSITAL QUICK MANUAL Profibus DP Interface Absolute Encoder | |

|

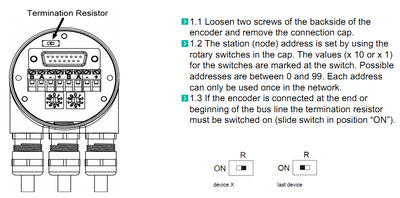

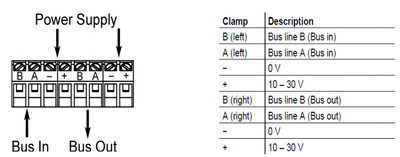

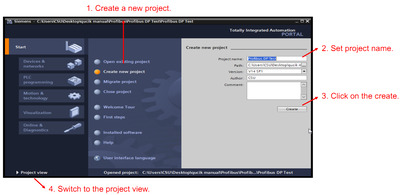

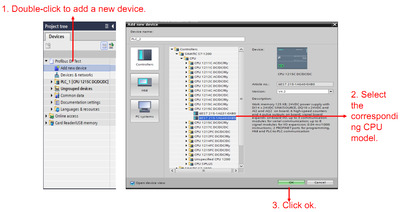

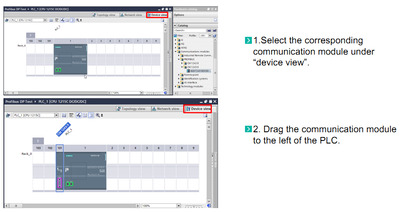

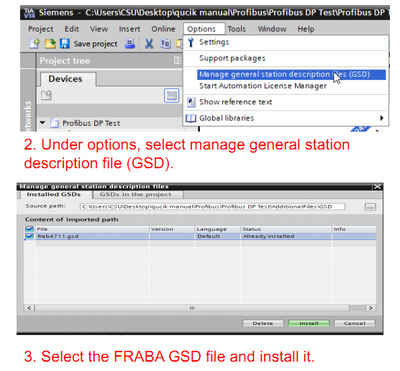

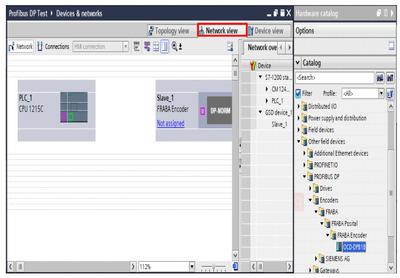

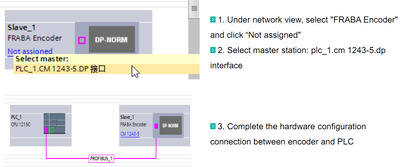

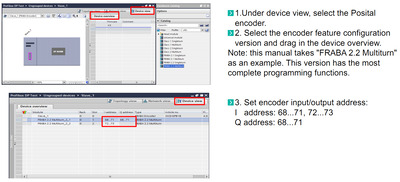

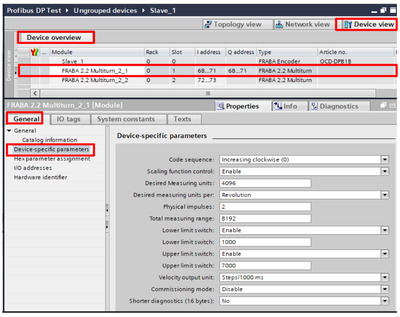

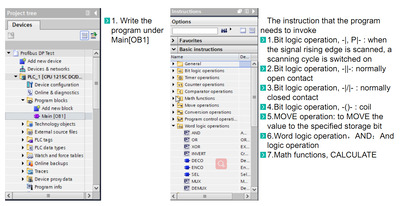

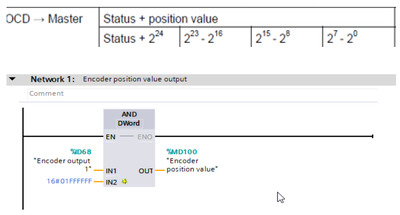

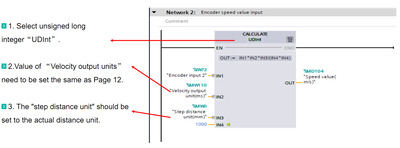

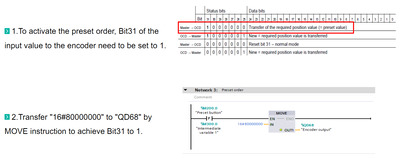

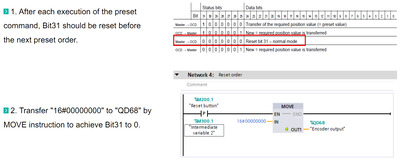

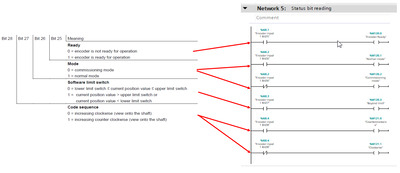

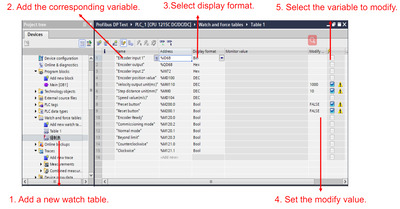

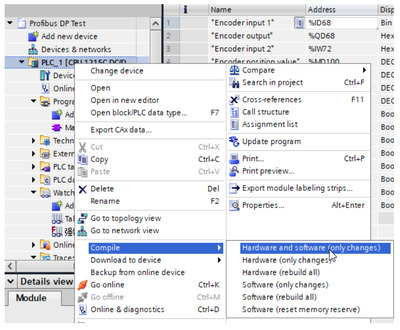

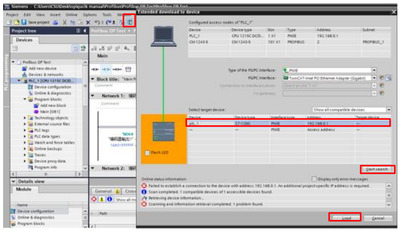

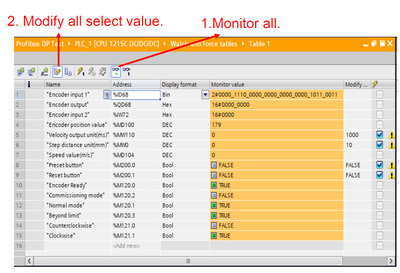

Sample: OCD-DPC1B-1213-C10S-H3P configuration-gsd-ixarc-ocd-dpv0.zip - GSD file FRAB4711.gsd QUICK MANUAL Profibus DP Interface Absolute Encoder.pdf manual-ixarc-ocd-dp.pdf - Absolute Rotary Encoder with Profibus-DP-Interface OCD-DPC1B-XXXX-XXXX-XXX User Manual UPDATE 15/04/2025 - TIA V15 Example - Absolute Encoder Example.zip Configuration.jpg Fraba Absolute Encoder.pdf FRABA Function Block.pdf FRABA_Absolute_Encoder.zip - ap15 TIA PORTAL project manual-ixarc-ocd-dp.pdf DEVICE CONNECTION Connecting Bus Lines and Power Supply Notes: The power supply has to be connected once (no matter which clamps). If the terminating resistor is switched on, the outgoing bus lines are disconnected. Cable Connection COMMNUNICATION CONNECTION PLC Settings Communication Module Setting Import GSD File Profibus DP Encoder Setting 1. Under network view, select “Other field devices”→“Porfibus Profibus DP Interface Connection Encoder Input/output Address Setting Encoder Profibus Address Setting Encoder Parameter Settings Select “Device view”→select “Device overview”→Right click on the “FRABA 2.2 Multiturn”→ “General”→“Devicespecific parameters”, encoder parameter setting: Program Blocks Network 1: Encoder Position Value Output 1. Encoder output value Bit0-Bit24: position value Network 2: Encoder Speed Value Input Network 3: Preset Order Network 4: Reset Order Network 5: Status Bit Reading Watch and Force Table Compile 1. Right-click PLC→ select "compile" → select "hardware and software (only changes)". Download Configuration to PLC 1. Click the download button. Watch and Force 1.After switching to online, observe the parameters of each variable.

| |

|

| |

| Всего комментариев: 0 | |