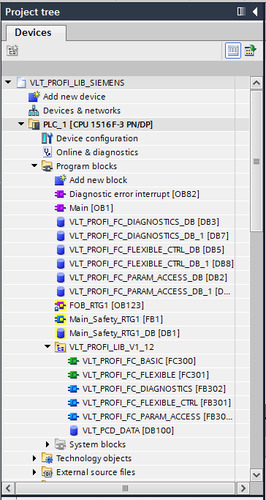

VLT_PROFI_LIB_SIEMENS.zip

Function_Blocks_with_SIEMENS_TIA_Portal_PG_AU326537640107en-000101_M0021501.pdf

VLT_PROFI_LIB_SIEMENS.zap15 - SIEMENS TIA Portal V15 Example

VLT_PROFI_LIB_V1_12.zal15 - SIEMENS TIA Portal V15 Library

GSDML-V2.32-Danfoss-FC-20170530.xml - PROFINET GSDML Danfoss FC PN GSDML-V2.32-Danfoss-FC-20170530.xml

da02040a.gsd - da02040a.gsd PROFIBUS GSD Danfoss Drives A/S FC 300 Series FC100/200/300 series revision 2.14 DPV1

VLT_PROFIBUS_GSD_2010-11-03.zip - Danfoss Drives PROFIBUS GSD files

DA010409.GSD - DMS300 PROFIBUS DPV0

DA02040A.gsd - FC 100 200 300

da020406.gsd - FCD 300 3MB DPV0

da030406.GSD - FCD 300 3MB DPV1

da020407.gsd - FCD 300 12MB DPV0

da030407.GSD - FCD 300 12MB DPV1

DA01040B.gsd - FCD 302

da020403.gsd - FCM 300 3MB DPV0

da030403.GSD - FCM 300 3MB DPV1

da020408.gsd - FCM 300 12MB DPV0

da030408.GSD - FCM 300 12MB DPV1

SSPM08A8.GSD - MCD200

da020404.gsd - VLT 2800 3Mb DPV0

da030404.GSD - VLT 2800 3Mb DPV1

da020405.gsd - VLT 2800 12MB DPV0

da030405.GSD - VLT 2800 12MB DPV1

da030402.gsd - VLT 5000 6000 8000 DPV0

da040402.GSD - VLT 5000 6000 8000 DPV1

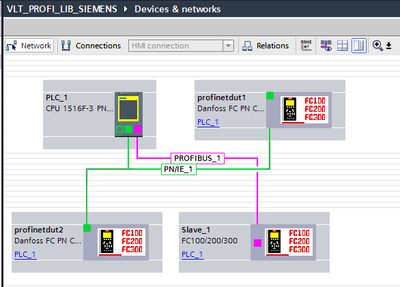

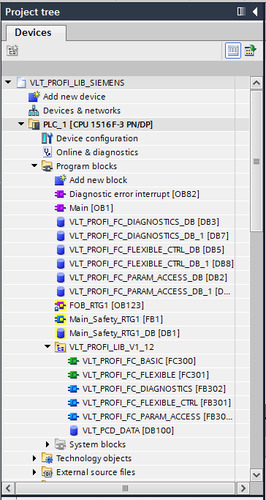

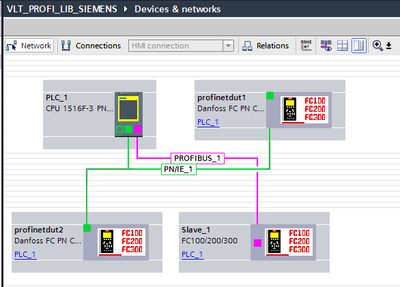

CPU 1516F-3 PN/DP 6ES7 516-3FN01-0AB0 V2.5

VLT_PROFI_FC_BASIC FC300

//-------------------------------------------------------------------------------------------------------------

// VLT_PROFI_FC_BASIC: Rev. V1.12

// Valid for S7-1200 and S7-1500 Type CPU's.

// Block handles communication with a VLT frequency converter. Either Trough PROFINET OR PROFIBUS.

// The FC handles basic needs and extraction of Motor current.

// PROFINET PPO type is PPO6 (4 words read/Write). PCD2 and PCD3 must be configured for Motor Current.

// PROFIBUS PPO type is PPO2 (6 words read/Write). PCD2 and PCD3 must be configured for Motor Current.

// Can be done in HW config of S7, on the Drive LCP or MCT10.

//-------------------------------------------------------------------------------------------------------------

//------------------------------------Standard - Control bits--------------------------------------------------

//Can be used locally in Block.

#AlwaysOff := false;

#AlwaysOn := TRUE;

//------------------------------------Standard - Control bits--------------------------------------------------

//------------------------------------Read data from fieldbus--------------------------------------------------

// Actual data size that is read depends on the Array size.

// Minimum size is 4 words.

// PPO type can be larger but only the 4 first words are read.

// Return value for DPRD and DPWR for PNET Comm. 0=No fault.

#RETVAL := DPRD_DAT(LADDR := #ADR, RECORD => #RDRaw_Data); // Read Raw Data

#COMM_ERR := #RETVAL;

//------------------------------------Read data from fieldbus--------------------------------------------------

//------------------------------------Read Raw Data is mapped with PCDRead------------------------------------------------------

#PCDRead.STW.BIT_00_CTRL_RDY := #RDRaw_Data[0].%X0;

#PCDRead.STW.BIT_01_DRV_RDY := #RDRaw_Data[0].%X1;

#PCDRead.STW.BIT_02_COAST_RDY := #RDRaw_Data[0].%X2;

#PCDRead.STW.BIT_03_TRIP := #RDRaw_Data[0].%X3;

#PCDRead.STW.BIT_04_ERROR := #RDRaw_Data[0].%X4;

#PCDRead.STW.BIT_05_RESERVED := #RDRaw_Data[0].%X5;

#PCDRead.STW.BIT_06_TRIPLOCK := #RDRaw_Data[0].%X6;

#PCDRead.STW.BIT_07_WARNING := #RDRaw_Data[0].%X7;

#PCDRead.STW.BIT_08_RUNNING_REF := #RDRaw_Data[0].%X8;

#PCDRead.STW.BIT_09_CTRL_SOURCE := #RDRaw_Data[0].%X9;

#PCDRead.STW.BIT_10_F_LIMIT_OK := #RDRaw_Data[0].%X10;

#PCDRead.STW.BIT_11_IN_OPR := #RDRaw_Data[0].%X11;

#PCDRead.STW.BIT_12_IN_AUTOSTART := #RDRaw_Data[0].%X12;

#PCDRead.STW.BIT_13_VOLT_MAX := #RDRaw_Data[0].%X13;

#PCDRead.STW.BIT_14_TORQ_MAX := #RDRaw_Data[0].%X14;

#PCDRead.STW.BIT_15_TIMER_EXD := #RDRaw_Data[0].%X15;

#PCDRead.MAV := #RDRaw_Data[1];

#PCDRead.PCD_02 := #RDRaw_Data[2];

#PCDRead.PCD_03 := #RDRaw_Data[3];

//------------------------------------Read Raw Data is mapped with PCDRead------------------------------------------------------

//------------------------------------Extraction of Main actual value--------------------------------------------

// Main Actual Value(MAV) is read from the Drive as 0 - 16384. Must be converted into 0 - 10000 (0.0 - 100.0 %)

IF #COMM_ERR = 0 THEN

#CalcSlope :=LREAL_TO_REAL (10000.0 / 16384.0);

#MAV := FLOOR_INT(#CalcSlope * #PCDRead.MAV); // Convert to percentage (0.0 - 100.0)

END_IF;

//------------------------------------Extraction of Main actual value--------------------------------------------

//------------------------------------Calculation of motor current----------------------------------------------

// Motor current is a 32 bit value hence 2 words read from the Drive need to be combined into a DWORD.

// Motor current is scaled with 2 decimal points (conversion index -2) hence division by 100.

IF #COMM_ERR = 0 THEN

#CurrentInternal := DINT_TO_DWORD(#PCDRead.PCD_02); // PCD02 is high word of Motor current

#CurrentInternal := SHL_DWORD(IN := #CurrentInternal, N := 16); // Shift high word of Motor current 16 bits to the left

#CurrentInternal := #CurrentInternal + DINT_TO_DWORD(#PCDRead.PCD_03); // PCD03 is low word of Motor current

#MOTORCURRENT := DINT_TO_LREAL(#CurrentInternal) / 100.0;

END_IF;

//------------------------------------Calculation of Motor current----------------------------------------------

//------------------------------------Mask out Drive status bit's-----------------------------------------------

IF #COMM_ERR = 0 THEN

#READY := (#PCDRead.STW.BIT_00_CTRL_RDY AND #PCDRead.STW.BIT_01_DRV_RDY AND #PCDRead.STW.BIT_02_COAST_RDY AND #PCDRead.STW.BIT_09_CTRL_SOURCE); // Drive ready to start from Fieldbus

#RUNNING := #PCDRead.STW.BIT_11_IN_OPR; // Drive is started but not necessarily running on reference speed.

#RUN_ON_REF := #PCDRead.STW.BIT_08_RUNNING_REF; // Running on reference

#WARNING := #PCDRead.STW.BIT_07_WARNING; // Warning present

#FAULT := (#PCDRead.STW.BIT_04_ERROR OR #PCDRead.STW.BIT_03_TRIP OR #PCDRead.STW.BIT_06_TRIPLOCK); // Fault present. Trip or Trip lock

ELSE

#READY := FALSE;

#FAULT := TRUE;

END_IF;

//------------------------------------Mask out Drive status bit's-----------------------------------------------

//------------------------------------Default settings of Controlword-------------------------------------------

// Prepare all Controlword Bit's to default values so that

// they are in a "ready to start" mode. CTW =043Ch

#PCDWrite.CTW.BIT_00_PRESET_REF_1 := FALSE;

#PCDWrite.CTW.BIT_01_PRESET_REF_2 := FALSE;

IF #DRV_EN THEN

#PCDWrite.CTW.BIT_02_DC_BRAKE_RAMP := TRUE;

#PCDWrite.CTW.BIT_03_COAST_INV := TRUE;

#PCDWrite.CTW.BIT_04_QSTP_RMP := TRUE;

#PCDWrite.CTW.BIT_05_HLD_RMP := TRUE;

ELSE

#PCDWrite.CTW.BIT_02_DC_BRAKE_RAMP := FALSE;

#PCDWrite.CTW.BIT_03_COAST_INV := FALSE;

#PCDWrite.CTW.BIT_04_QSTP_RMP := FALSE;

#PCDWrite.CTW.BIT_05_HLD_RMP := FALSE;

END_IF;

#PCDWrite.CTW.BIT_06_START := FALSE;

#PCDWrite.CTW.BIT_07_RESET := FALSE;

#PCDWrite.CTW.BIT_08_JOG := FALSE;

#PCDWrite.CTW.BIT_09_RAMP_1_2 := FALSE;

#PCDWrite.CTW.BIT_10_DATA_VALID := TRUE;

#PCDWrite.CTW.BIT_11_RLY_1_ON := FALSE;

#PCDWrite.CTW.BIT_12_RLY_2_ON := FALSE;

#PCDWrite.CTW.BIT_13_SETUP_SEL_1 := FALSE;

#PCDWrite.CTW.BIT_14_SETUP_SEL_2 := FALSE;

#PCDWrite.CTW.BIT_15_REVERSE := FALSE;

//------------------------------------Default settings of Controlword-------------------------------------------

//------------------------------------Drive control bit's-------------------------------------------------------

#PCDWrite.CTW.BIT_06_START := #RUN AND NOT #FAULT; // Start the Drive if there is no pending Fault.

#PCDWrite.CTW.BIT_15_REVERSE := #REVERSE; // Set Drive to Reverse Mode. Ensure Par. 4-10 is set to "Both Directions"

#PCDWrite.CTW.BIT_07_RESET := #RESET; // Reset pending Fault

//------------------------------------Drive control bit's-------------------------------------------------------

//------------------------------------Reference value limit check------------------------------------------------

// Must be between 0 - 10000. Ensure reference speed is within limits.

IF #REF_VALUE >= 10000 THEN

#REF_VALUE := (10000);

END_IF;

IF #REF_VALUE < 0 THEN

#REF_VALUE := 0;

END_IF;

//------------------------------------Reference value limit check------------------------------------------------

//------------------------------------PCDWrite is mapped with WriteRaw data--------------------------------------------------

#WRRaw_Data[0].%X0 := #PCDWrite.CTW.BIT_00_PRESET_REF_1;

#WRRaw_Data[0].%X1 := #PCDWrite.CTW.BIT_01_PRESET_REF_2;

#WRRaw_Data[0].%X2 := #PCDWrite.CTW.BIT_02_DC_BRAKE_RAMP;

#WRRaw_Data[0].%X3 := #PCDWrite.CTW.BIT_03_COAST_INV;

#WRRaw_Data[0].%X4 := #PCDWrite.CTW.BIT_04_QSTP_RMP;

#WRRaw_Data[0].%X5 := #PCDWrite.CTW.BIT_05_HLD_RMP;

#WRRaw_Data[0].%X6 := #PCDWrite.CTW.BIT_06_START;

#WRRaw_Data[0].%X7 := #PCDWrite.CTW.BIT_07_RESET;

#WRRaw_Data[0].%X8 := #PCDWrite.CTW.BIT_08_JOG;

#WRRaw_Data[0].%X9 := #PCDWrite.CTW.BIT_09_RAMP_1_2;

#WRRaw_Data[0].%X10 := #PCDWrite.CTW.BIT_10_DATA_VALID;

#WRRaw_Data[0].%X11 := #PCDWrite.CTW.BIT_11_RLY_1_ON;

#WRRaw_Data[0].%X12 := #PCDWrite.CTW.BIT_12_RLY_2_ON;

#WRRaw_Data[0].%X13 := #PCDWrite.CTW.BIT_13_SETUP_SEL_1;

#WRRaw_Data[0].%X14 := #PCDWrite.CTW.BIT_14_SETUP_SEL_2;

#WRRaw_Data[0].%X15 := #PCDWrite.CTW.BIT_15_REVERSE;

#WRRaw_Data[2] := #PCDWrite.PCD_02;

#WRRaw_Data[3] := #PCDWrite.PCD_03;

//------------------------------------PCDWrite is mapped with WriteRaw data--------------------------------------------------

//------------------------------------Reference value limit check------------------------------------------------

// Must be between 0 - 10000. Ensure reference speed is within limits.

IF #REF_VALUE >= 10000 THEN

#REF_VALUE := 10000;

END_IF;

IF #REF_VALUE < 0 THEN

#REF_VALUE := 0;

END_IF;

//------------------------------------Reference value limit check------------------------------------------------

//------------------------------------Prepare Reference value----------------------------------------------------

// PCD Write block position 1. Fit's with PPO type mapping

// Convert 10000 into 16384 which equals 4000h. 10000 = 100.00%

#CalcSlope := LREAL_TO_REAL (16384.0 / 10000.0);

#PCDWrite.MRV := FLOOR_INT(#CalcSlope * #REF_VALUE); // Convert to percentage (0.0 - 100.0)

#WRRaw_Data[1] := #PCDWrite.MRV; // Main reference value is Mapped with write Raw Data

//------------------------------------Prepare Reference value----------------------------------------------------

//------ADR------------------------------Send Data------------------------------------------------------------------

// Return value for DPRD and DPWR for PNET Comm. 0=No fault

IF #COMM_ERR = 0 THEN

#RETVAL := DPWR_DAT(LADDR := #ADR, RECORD := #WRRaw_Data); //#Write Raw Data);

#COMM_ERR := #RETVAL;

END_IF;

//------------------------------------Send Data------------------------------------------------------------------

//------------------------------------Ensure ENO is TRUE always--------------------------------------------------

ENO := TRUE;

//------------------------------------Ensure ENO is TRUE always--------------------------------------------------

VLT_PROFI_FC_FLEXIBLE

//-------------------------------------------------------------------------------------------------------------

// VLT_PROFI_FC_FLEXIBLE: Rev. V1.12

// Valid for S7-1200 and S7-1500 Type CPU's.

// Block handles communication with a VLT frequency converter. Either Trough PROFINET OR PROFIBUS.

// The FC handles extended needs allowing access to all needed parameters.

// Can be done in HW config of S7, on the Drive LCP or MCT10.

//-------------------------------------------------------------------------------------------------------------

//------------------------------------Standard - Control bits--------------------------------------------------

//Can be used locally in Block.

#AlwaysOff := FALSE;

#AlwaysOn := TRUE;

//------------------------------------Standard - Control bits--------------------------------------------------

//------------------------------------Read data from fieldbus--------------------------------------------------

// Read data from Drive. PPO types 3, 4, 6, 7, 8 Allowed.

// Return value for DPRD and DPWR for PNET Comm. 0=No fault.

#RETVAL1 := DPRD_DAT(LADDR := #ADR, RECORD => #RDRaw_Data); // Read Raw Data

#COMM_ERR := #RETVAL1;

//------------------------------------Read data from fieldbus--------------------------------------------------

//------------------------------------Raw Read data to PCDRead------------------------------------------------------

#PCDREAD.STW.BIT_00_CTRL_RDY := #RDRaw_Data[0].%X0;

#PCDREAD.STW.BIT_01_DRV_RDY := #RDRaw_Data[0].%X1;

#PCDREAD.STW.BIT_02_COAST_RDY := #RDRaw_Data[0].%X2;

#PCDREAD.STW.BIT_03_TRIP := #RDRaw_Data[0].%X3;

#PCDREAD.STW.BIT_04_ERROR := #RDRaw_Data[0].%X4;

#PCDREAD.STW.BIT_05_RESERVED := #RDRaw_Data[0].%X5;

#PCDREAD.STW.BIT_06_TRIPLOCK := #RDRaw_Data[0].%X6;

#PCDREAD.STW.BIT_07_WARNING := #RDRaw_Data[0].%X7;

#PCDREAD.STW.BIT_08_RUNNING_REF := #RDRaw_Data[0].%X8;

#PCDREAD.STW.BIT_09_CTRL_SOURCE := #RDRaw_Data[0].%X9;

#PCDREAD.STW.BIT_10_F_LIMIT_OK := #RDRaw_Data[0].%X10;

#PCDREAD.STW.BIT_11_IN_OPR := #RDRaw_Data[0].%X11;

#PCDREAD.STW.BIT_12_IN_AUTOSTART := #RDRaw_Data[0].%X12;

#PCDREAD.STW.BIT_13_VOLT_MAX := #RDRaw_Data[0].%X13;

#PCDREAD.STW.BIT_14_TORQ_MAX := #RDRaw_Data[0].%X14;

#PCDREAD.STW.BIT_15_TIMER_EXD := #RDRaw_Data[0].%X15;

#PCDREAD.MAV := #RDRaw_Data[1];

#PCDREAD.PCD_02 := #RDRaw_Data[2];

#PCDREAD.PCD_03 := #RDRaw_Data[3];

#PCDREAD.PCD_04 := #RDRaw_Data[4];

#PCDREAD.PCD_05 := #RDRaw_Data[5];

#PCDREAD.PCD_06 := #RDRaw_Data[6];

#PCDREAD.PCD_07 := #RDRaw_Data[7];

#PCDREAD.PCD_08 := #RDRaw_Data[8];

#PCDREAD.PCD_09 := #RDRaw_Data[9];

//------------------------------------Raw read data to PCDRead------------------------------------------------------

//------------------------------------PCDWrite is mapped with Write Raw data--------------------------------------------------

#WRRaw_Data[0].%X0 := #PCDWRITE.CTW.BIT_00_PRESET_REF_1;

#WRRaw_Data[0].%X1 := #PCDWRITE.CTW.BIT_01_PRESET_REF_2;

#WRRaw_Data[0].%X2 := #PCDWRITE.CTW.BIT_02_DC_BRAKE_RAMP;

#WRRaw_Data[0].%X3 := #PCDWRITE.CTW.BIT_03_COAST_INV;

#WRRaw_Data[0].%X4 := #PCDWRITE.CTW.BIT_04_QSTP_RMP;

#WRRaw_Data[0].%X5 := #PCDWRITE.CTW.BIT_05_HLD_RMP;

#WRRaw_Data[0].%X6 := #PCDWRITE.CTW.BIT_06_START;

#WRRaw_Data[0].%X7 := #PCDWRITE.CTW.BIT_07_RESET;

#WRRaw_Data[0].%X8 := #PCDWRITE.CTW.BIT_08_JOG;

#WRRaw_Data[0].%X9 := #PCDWRITE.CTW.BIT_09_RAMP_1_2;

#WRRaw_Data[0].%X10 := #PCDWRITE.CTW.BIT_10_DATA_VALID;

#WRRaw_Data[0].%X11 := #PCDWRITE.CTW.BIT_11_RLY_1_ON;

#WRRaw_Data[0].%X12 := #PCDWRITE.CTW.BIT_12_RLY_2_ON;

#WRRaw_Data[0].%X13 := #PCDWRITE.CTW.BIT_13_SETUP_SEL_1;

#WRRaw_Data[0].%X14 := #PCDWRITE.CTW.BIT_14_SETUP_SEL_2;

#WRRaw_Data[0].%X15 := #PCDWRITE.CTW.BIT_15_REVERSE;

#WRRaw_Data[1] := #PCDWRITE.REF_VALUE;

#WRRaw_Data[2] := #PCDWRITE.PCD_02;

#WRRaw_Data[3] := #PCDWRITE.PCD_03;

#WRRaw_Data[4] := #PCDWRITE.PCD_04;

#WRRaw_Data[5] := #PCDWRITE.PCD_05;

#WRRaw_Data[6] := #PCDWRITE.PCD_06;

#WRRaw_Data[7] := #PCDWRITE.PCD_07;

#WRRaw_Data[8] := #PCDWRITE.PCD_08;

#WRRaw_Data[9] := #PCDWRITE.PCD_09;

//------------------------------------PCDWrite is mapped with Write Raw data--------------------------------------------------

//------------------------------------Send Data------------------------------------------------------------------

IF #RETVAL1 = 0 THEN

#RETVAL1 := DPWR_DAT(LADDR := #ADR, RECORD := #WRRaw_Data); // Write Raw Data

#COMM_ERR := #RETVAL1;

END_IF;

//------------------------------------Send Data------------------------------------------------------------------

//------------------------------------Ensure ENO is TRUE always--------------------------------------------------

ENO := TRUE;

//------------------------------------Ensure ENO is TRUE always--------------------------------------------------

VLT_PROFI_FC_DIAGNOSTICS FB302

//-------------------------------------------------------------------------------------------------------------

// VLT_PROFI_FC_DIAGNOSTICS: Rev. V1.12

// Valid for S7-1200 and S7-1500 Type CPU's.

// Block handles communication with a VLT frequency converter. Either Trough PROFINET OR PROFIBUS.

// Can be done in HW config of S7, on the Drive LCP or MCT10.

//-------------------------------------------------------------------------------------------------------------

#Static_1.AlarmCheckID := #ADDR; //Hardware identifier of the module to Alarm check ID

//RALRM is used to Read manufacture specific alarms

"RALRM_DB"(MODE := #Static_1.AlarmMode, //Mode

F_ID := #Static_1.AlarmCheckID, //Hardware identifier of the module

MLEN := #Static_1.AlarmMaxLength, //Maximum length of the interrupt information to be received in bytes

NEW => #Static_1.AlarmReceived, //New interrupt was received

STATUS => #Static_1.AlarmStatus, //Error code

ID => #Static_1.AlarmFromID, //Hardware identifier of the module from which the interrupt was received

LEN => #Static_1.AlarmLength, //Length of the received interrupt information

TINFO := #Static_1.TI_DiagnosticInterrupt, //Target range for OB start and management information

AINFO := #AINFOManufacture); //Target range for header information and additional interrupt information

// Identify the Profibus or Profinet slave

#SlaveType := #Static_1.TI_DiagnosticInterrupt.slv_prfl; //slv_prfl to slave type

IF #SlaveType = 3 THEN //Profibus slave (Byte#16#0011)

#Profibus_slave := 1;

#Profinet_slave := 0;

END_IF;

IF #SlaveType = 8 THEN //Profinet IO (Byte#16#1000)

#Profibus_slave := 0;

#Profinet_slave := 1;

END_IF;

//Extract error information for PROFINET IO

IF #Profinet_slave AND #Static_1.AlarmReceived AND (#AINFOManufacture.W6_interrupt_type = 16#0001) THEN

IF (#AINFOManufacture.W26_Add_W0_format_ID = 16#7FFF) THEN

#ALARM_1 := #AINFOManufacture.D28_AlarmWord; // Profinet IO Alarm word

#WARNING_1 := #AINFOManufacture.D32_WarnWord; // Profinet IO Warning word

#Static_1.AlarmReceived := 0;

END_IF;

IF (#AINFOManufacture.W26_Add_W0_format_ID = 16#8000) THEN

#CH_ERR_TYP := DWORD_TO_WORD(SHR(IN := (#AINFOManufacture.D32_WarnWord), N := 16)); // Channel Error Type

#Static_1.AlarmReceived := 0;

END_IF;

END_IF;

//Extract error information for PROFIBUS slave

IF #Profibus_slave AND #Static_1.AlarmReceived AND #AINFOManufacture.W2_block_length = 16#0001 THEN

#ProfibusAlarm := #AINFOManufacture.W4_version;

#ProfibusAlarm := SHL(IN := (#ProfibusAlarm), N := 16);

#TempAlarm := #AINFOManufacture.W6_interrupt_type;

#ALARM_1 := #ProfibusAlarm OR #TempAlarm; // Profibus Alarm Word

#Static_1.AlarmReceived := 0;

#ProfibusWarning := #AINFOManufacture.W12_comp_slot_num;

#ProfibusWarning := SHL(IN := (#ProfibusWarning), N := 16);

#TempWarning := #AINFOManufacture.W14_submodule_slot_num;

#WARNING_1 := #ProfibusWarning OR #TempWarning; //Profibus "WARNING" Word

#Static_1.AlarmReceived := 0;

END_IF;

// Clear the PROFINET Alarm/Warning data if alarm is reset

IF #Static_1.AlarmReceived THEN

IF #AINFOManufacture.W6_interrupt_type = 16#000C THEN

#CH_ERR_TYP := 0;

#ALARM_1 := 0;

#WARNING_1 := 0;

#Static_1.AlarmReceived := 0;

END_IF;

END_IF;

// Clear the PROFIBUS Alarm/Warning data if alarm is reset

IF #Static_1.AlarmReceived THEN

IF #AINFOManufacture.W2_block_length = 2 THEN

#CH_ERR_TYP := 0;

#ALARM_1 := 0;

#WARNING_1 := 0;

#Static_1.AlarmReceived := 0;

END_IF;

END_IF;

VLT_PROFI_FC_FLEXIBLE_CTRL FB301

//-------------------------------------------------------------------------------------------------------------

// VLT_PROFI_FC_FLEXIBLE_CTRL: Rev. V1.12

// Valid for S7-1200 and S7-1500 Type CPU's.

// This FB is to be used together with "VLT_PROFI_FC_FLEXIBLE"

// This FB is designed to work with the FCPROFILE on the VLT which is the default setting.

// Block Manages control and status bits' as well as Reference value. The default values on the Input Interface definitions

// are set as if they are not assigned an outside value, it will bring the VLT in a "Ready to Start" State.

//-------------------------------------------------------------------------------------------------------------

//------------------------------------Settings of Controlword--------------------------------------------------

// Prepare all Controlword Bit's to default values so that

// they are in a "ready to start" mode. CTW =043Ch

#PCDWrite.CTW.BIT_00_PRESET_REF_1 := #PRESET_REF_1;

#PCDWrite.CTW.BIT_01_PRESET_REF_2 := #PRESET_REF_2;

#PCDWrite.CTW.BIT_02_DC_BRAKE_RAMP := #DC_BRAKE_RAMP;

#PCDWrite.CTW.BIT_03_COAST_INV := #COAST_INV;

#PCDWrite.CTW.BIT_04_QSTP_RMP := #QSTP_RMP;

#PCDWrite.CTW.BIT_05_HLD_RMP := #HLD_RMP;

#PCDWrite.CTW.BIT_06_START := #START;

#PCDWrite.CTW.BIT_07_RESET := #RESET;

#PCDWrite.CTW.BIT_08_JOG := #JOG;

#PCDWrite.CTW.BIT_09_RAMP_1_2 := #RAMP_1_2;

#PCDWrite.CTW.BIT_10_DATA_VALID := #DATA_VALID;

#PCDWrite.CTW.BIT_11_RLY_1_ON := #RLY_1_ON;

#PCDWrite.CTW.BIT_12_RLY_2_ON := #RLY_2_ON;

#PCDWrite.CTW.BIT_13_SETUP_SEL_1 := #SETUP_SEL_1; // Multi setup in P. 0-10 must be selected.

#PCDWrite.CTW.BIT_14_SETUP_SEL_2 := #SETUP_SEL_2; // Multi setup in P. 0-10 must be selected.

#PCDWrite.CTW.BIT_15_REVERSE := #REVERSE;

//------------------------------------Settings of Controlword---------------------------------------------------

//------------------------------------Set reference speed-------------------------------------------------------

#PCDWrite.REF_VALUE := #REF_VALUE; // Reference speed is a RAW value - 16384 to + 16384.

//------------------------------------Set reference speed-------------------------------------------------------

//------------------------------------Mask out Drive status bit's-----------------------------------------------

// These are those considered to be used most often, there fore put in as "OUTPUT's" on the FB.

#READY := (#PCDRead.STW.BIT_00_CTRL_RDY AND #PCDRead.STW.BIT_01_DRV_RDY AND #PCDRead.STW.BIT_02_COAST_RDY AND #PCDRead.STW.BIT_09_CTRL_SOURCE); // Drive ready to start from Fieldbus

#RUNNING := #PCDRead.STW.BIT_11_IN_OPR; // Drive is started but not necessarily running on reference speed.

#RUN_ON_REF := #PCDRead.STW.BIT_08_RUNNING_REF; // Running on reference

#WARNING := #PCDRead.STW.BIT_07_WARNING; // Warning present

#FAULT := (#PCDRead.STW.BIT_04_ERROR OR #PCDRead.STW.BIT_03_TRIP OR #PCDRead.STW.BIT_06_TRIPLOCK); // Fault present. Trip or Trip lock

//------------------------------------Mask out Drive status bit's-----------------------------------------------

//------------------------------------Extraction of Main actual value--------------------------------------------

#MAV := #PCDRead.MAV; // Main Actual Value(MAV) is read from the Drive as - 16384 to + 16384.

//------------------------------------Extraction of Main actual value--------------------------------------------

//------------------------------------Initialize input's to their default values--------------------------------

// This set's the default values for the input definitions. This ensures that if an input is not configured.

// it will always have it initial default value

#PRESET_REF_1 := FALSE;

#PRESET_REF_2 := FALSE;

#DC_BRAKE_RAMP := TRUE;

#COAST_INV := TRUE;

#QSTP_RMP := TRUE;

#HLD_RMP := TRUE;

#START := FALSE;

#RESET := FALSE;

#JOG := FALSE;

#RAMP_1_2 := FALSE;

#RLY_1_ON := FALSE;

#RLY_2_ON := FALSE;

#SETUP_SEL_1 := FALSE;

#SETUP_SEL_2 := FALSE;

#REVERSE := FALSE;

#DATA_VALID := TRUE;

//------------------------------------Initialize input's to their default values--------------------------------

//------------------------------------Ensure ENO is TRUE always--------------------------------------------------

ENO := TRUE;

//------------------------------------Ensure ENO is TRUE always--------------------------------------------------

VLT_PROFI_FC_PARAM_ACCESS FB300

//-------------------------------------------------------------------------------------------------------------

// VLT_PROFI_FC_PARAM_ACCESS: Rev. V1.12

// Valid for S7-1200 and S7-1500 Type CPU's.

// Block handles communication with a VLT frequency converter. Either Trough PROFINET OR PROFIBUS.

// Acyclic communication with VLT.

// Can be done in HW config of S7, on the Drive LCP or MCT10.

//-------------------------------------------------------------------------------------------------------------

#Static_bool_3 := NOT #RD_WR; // Static bit is NOT of RD_WR

// Initializing the value with Zero

IF (#EXECUTE AND NOT #Static_bool_5) THEN

#DONE := 0;

#BUSY := 0;

#FAULT := 0;

#FALUT_CODE := 0;

#Static_busy := 0;

#Static_done := 0;

#Static_fault := 0;

FILL_BLK(IN := 0,

COUNT := 6,

OUT => #Response_rec.Res_Data[1]); // Read array initializing the value with Zero

END_IF;

//Parameter Read Value Operation Enable

IF (#Static_bool_3) AND (#EXECUTE AND NOT #Static_bool_5) THEN //Read with rising edge command

#Case_sequence_selection := 11; //Case sequence selection

#RD_VALUE := 0; //Read value to zero

#Static_bool_1 := 1; //Start request enable

//Parameter Write Value Operation Enable

ELSIF (#RD_WR) AND (#EXECUTE AND NOT #Static_bool_5) THEN //Write with rising edge command

#Case_sequence_selection := 11; //Case sequence selection

#RD_VALUE := 0; //Read value to zero

#Static_bool_2 := 1; //Start request enable

END_IF;

//Read or Write request parameter values are generally transferred via the header of the RECORD data record

#Request_rec.Req_Header.Request_Ref := B#16#01; //Request reference

#Request_rec.Req_Header.Axis_Number := B#16#00; //Axis number

#Request_rec.Req_Header.No_of_Parameter := B#16#01; //Number of parameter

#Request_rec.Req_ParaAddress.Attribute := B#16#10; //Attribute

#Request_rec.Req_ParaAddress.Num_of_elements := B#16#01; //Number of element

#Request_rec.Req_ParaAddress.Parameter_Num := (#PAR_NO); //Parameter number

#Request_rec.Req_ParaAddress.Subindex := #INDEX; //Sub index

//Read Request parameter values are generally transferred via the header of the RECORD data record

IF #Static_bool_1 THEN

#Request_rec.Req_Header.Request_ID := 16#51; //Read request, 51=Read request, Dword format

END_IF;

// Write Request request parameter values are generally transferred via the header of the RECORD data record

IF #Static_bool_2 THEN

#Request_rec.Req_Header.Request_ID := B#16#52; //Change request, 52=Write request, Dword format

#Request_rec.Req_ParaAddress.Write_Format := B#16#43; //Write format

#Request_rec.Req_ParaAddress.Write_Num_Of_Value := B#16#01; //Write number of value

//Write value

#Request_rec.Req_ParaAddress.Write_Value[4] := WORD_TO_BYTE(DWORD_TO_WORD(#WR_VALUE));

#Request_rec.Req_ParaAddress.Write_Value[3] := WORD_TO_BYTE(DWORD_TO_WORD(SHR(IN := (#WR_VALUE), N := 8)));

#Request_rec.Req_ParaAddress.Write_Value[2] := WORD_TO_BYTE(DWORD_TO_WORD(SHR(IN := (#WR_VALUE), N := 16)));

#Request_rec.Req_ParaAddress.Write_Value[1] := WORD_TO_BYTE(DWORD_TO_WORD(SHR(IN := (#WR_VALUE), N := 24)));

END_IF;

CASE #Case_sequence_selection OF

11: // Statement section case 11

IF (#Static_bool_1 OR #Static_bool_2) THEN

#Static_bool_6 := 1;

#BUSY := 1;

END_IF;

;

IF #Static_bool_6 AND NOT #Static_done THEN //Start WRREC request

#WRREC_Instance(REQ := TRUE, //WRREC Instance

ID := #ADR,

INDEX := 47,

BUSY => #Static_busy,

DONE => #Static_done,

ERROR => #Static_fault,

LEN := 16,

RECORD := #Request_rec,

STATUS => #Static_stored_status);

END_IF;

;

IF #Static_done OR #Static_fault AND NOT #Static_busy THEN //Write request status, done or fault or busy

#Case_sequence_selection := 12; //12 Case sequence selection

END_IF;

;

12: // Statement section case 12

IF #Static_done = 1 THEN //Check parameter write is done

#Case_sequence_selection := 13; //13 Case sequence selection

#DONE := 0;

#BUSY := 1;

#Static_bool_4 := 1;

;

ELSIF #Static_fault = 1 THEN //Check write record is fault

#Case_sequence_selection := 50; //50 Case sequence selection

#FAULT := 1;

#BUSY := 0;

#FALUT_CODE := (#Static_stored_status); //Fault code value

END_IF;

;

13: // Statement section case 13

IF #Static_bool_4 AND (NOT #Static_valid) THEN //Start RDREC response

#RDREC_Instance(REQ := TRUE, //RDREC Instance

ID := #ADR,

INDEX := 47,

MLEN := 10,

BUSY => #Static_busy,

LEN => #Response_Len,

STATUS => #Static_stored_status,

VALID => #Static_valid,

RECORD := #Response_rec);

END_IF;

;

IF #Static_valid = 1 AND #Static_bool_3 THEN //Read response is valid

IF #Response_rec.Res_Data[1] = 16#44 OR #Response_rec.Res_Header.Request_ID = 16#D1 THEN //Check the parameter format

#FAULT := 1;

#DONE := 0;

#BUSY := 0;

#Case_sequence_selection := 60; //Fault State

#RD_VALUE := 0;

;

ELSE

#FAULT := 0;

#DONE := 1;

#BUSY := 0;

#Case_sequence_selection := 14; //Done State

END_IF;

;

ELSIF #Static_busy = 1 THEN //Busy State

#Case_sequence_selection := 13;

#BUSY := 1;

END_IF;

;

IF #Static_valid = 1 AND #RD_WR THEN

IF #Response_rec.Res_Data[1] = 16#44 OR #Response_rec.Res_Header.Request_ID = 16#82 THEN // Statement section IF

#FAULT := 1;

#DONE := 0;

#BUSY := 0;

#Case_sequence_selection := 60; //Fault State

#RD_VALUE := 0;

ELSE

#FAULT := 0;

#DONE := 1;

#BUSY := 0;

#Case_sequence_selection := 15; //Done State

END_IF;

;

ELSIF #Static_busy = 1 THEN //Busy State

#Case_sequence_selection := 13;

#BUSY := 1;

END_IF;

;

14: // Statement section case 14

// Parameter Read done state

#DONE := 1;

#BUSY := 0;

#FALUT_CODE := 16#FF; //If error is not present in the read or write operation and then error code is set as 0xFF. Since 0x00 is valid error code for Unknown Parameter.

// Read value is converted from Word to DWord

#Temp_word_high := SHL(IN := BYTE_TO_WORD(#Response_rec.Res_Data[3]), N := 8);

#Temp_word_low := BYTE_TO_WORD(#Response_rec.Res_Data[4]);

#Temp_word1 := #Temp_word_high XOR #Temp_word_low;

#Temp_word_high := SHL(IN := BYTE_TO_WORD(#Response_rec.Res_Data[5]), N := 8);

#Temp_word_low := BYTE_TO_WORD(#Response_rec.Res_Data[6]);

#Temp_word2 := #Temp_word_high XOR #Temp_word_low;

#Temp_dword_high := SHL(IN := WORD_TO_DWORD(#Temp_word1), N := 16);

#Temp_dword_low := WORD_TO_DWORD(#Temp_word2);

#RD_VALUE := (#Temp_dword_high XOR #Temp_dword_low); //Read Value

;

15: // Statement section case 15

// Parameter Write done state

#DONE := 1;

#BUSY := 0;

#FALUT_CODE := 16#FF; //If error is not present in the read or write operation and then error code is set as 0xFF. Since 0x00 is valid error code for Unknown Parameter.

;

50: // Statement section case 50

// Parameter write Fault state

#FAULT := 1; //Fault status

#DONE := 0;

#BUSY := 0;

#FALUT_CODE := (#Static_stored_status); //Fault code value

;

60: // Statement section case 60

// Parameter Response error state

#FAULT := 1; //Fault status

#DONE := 0;

#BUSY := 0;

#Temp_word_high := SHL(IN := BYTE_TO_WORD(#Response_rec.Res_Data[3]), N := 8);

#Temp_word_low := BYTE_TO_WORD(#Response_rec.Res_Data[4]);

#FALUT_CODE := #Temp_word_high XOR #Temp_word_low; //Fault code moving to stored status

;

END_CASE;

IF NOT #EXECUTE THEN // If execute command is not present then zero value moved to below variables

#Static_bool_1 := 0;

#Static_bool_2 := 0;

#Static_bool_4 := 0;

#Static_bool_6 := 0;

#Static_valid := 0;

END_IF;

;

#Static_bool_5 := #EXECUTE; //Capturing the falling edge of Last value

|