DD190rev1_en.pdf

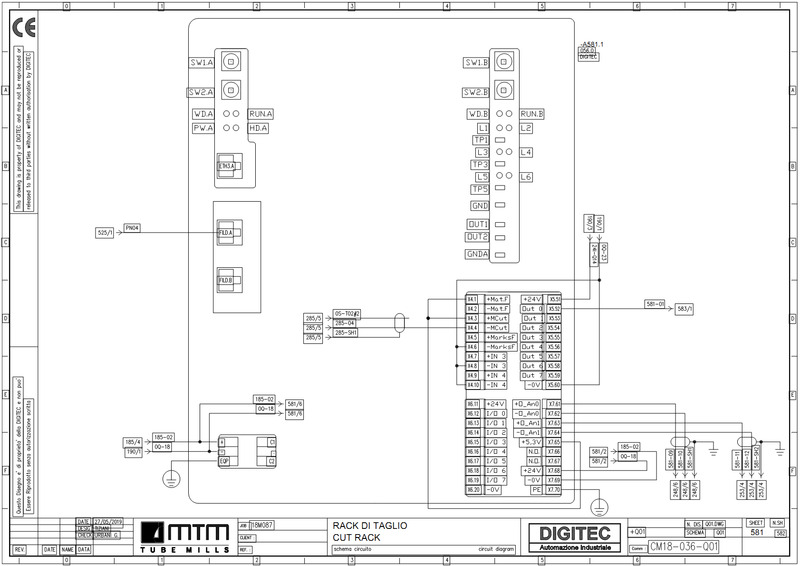

0560_example.pdf

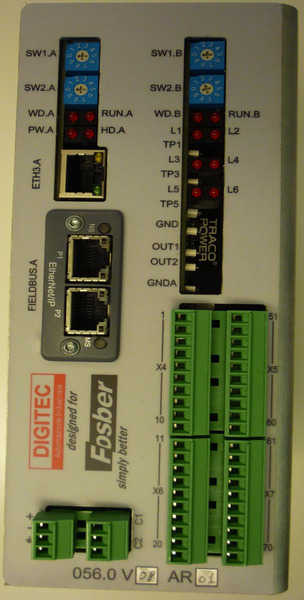

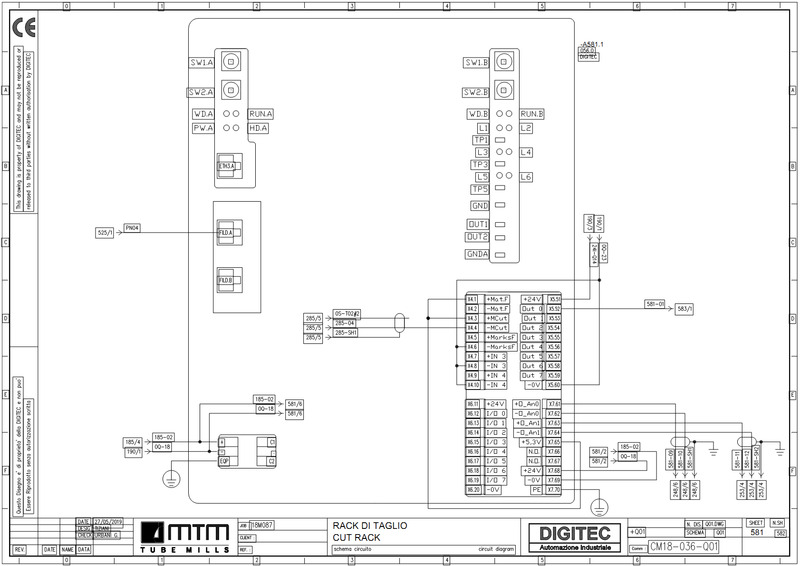

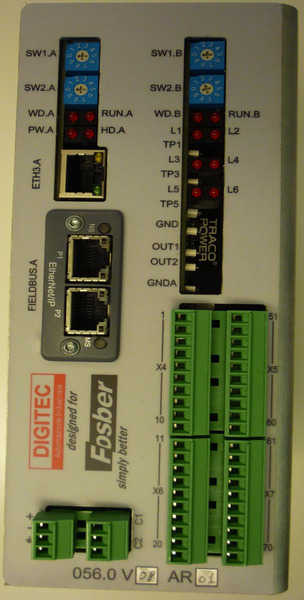

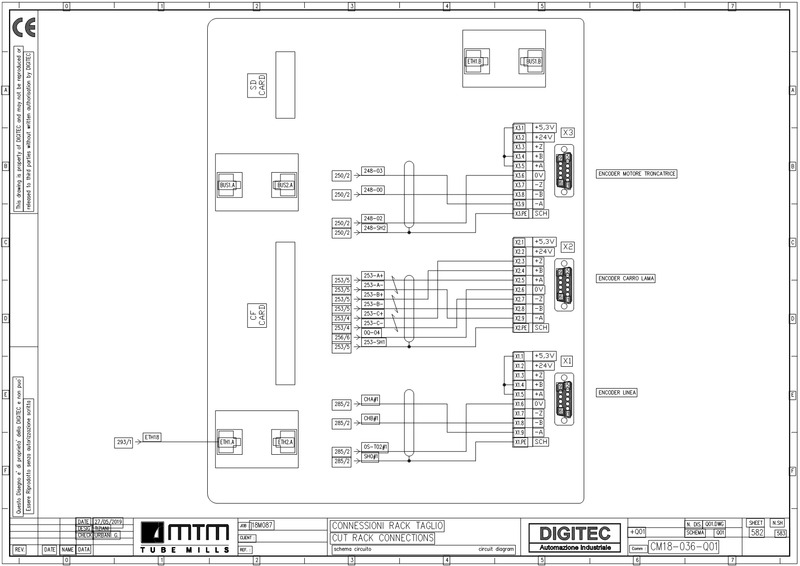

1. Rack description

The DIGITEC cards are housed in an aluminum housing for mounting on DIN rail.

Inside the system it consists of four tabs :

- supply card PC104 e fieldbus

- fieldbus card anybus cc m40

- PC104 card

- Input output card

The system has a input voltage ranging from 18V to 36V DC automatically selected and has a consumption of about 20-24W .

Work range temperature from 0 ° C to 60 ° C.

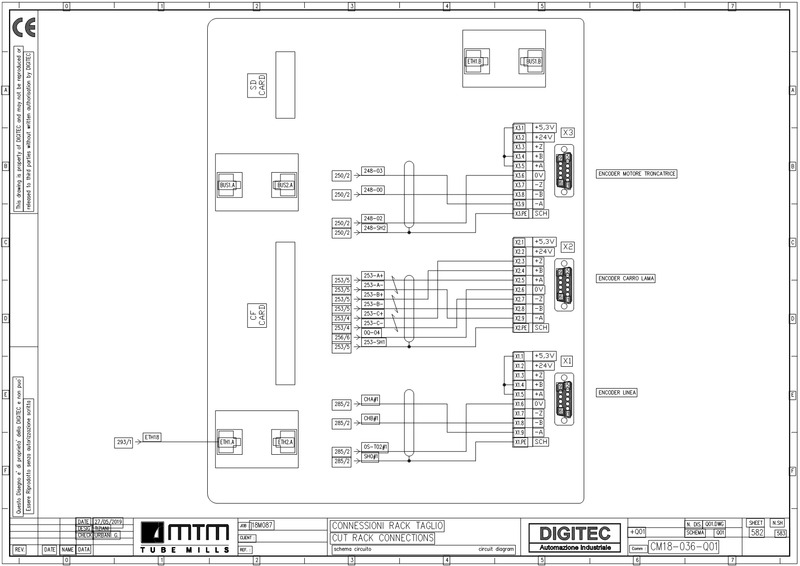

2. Hardware connection

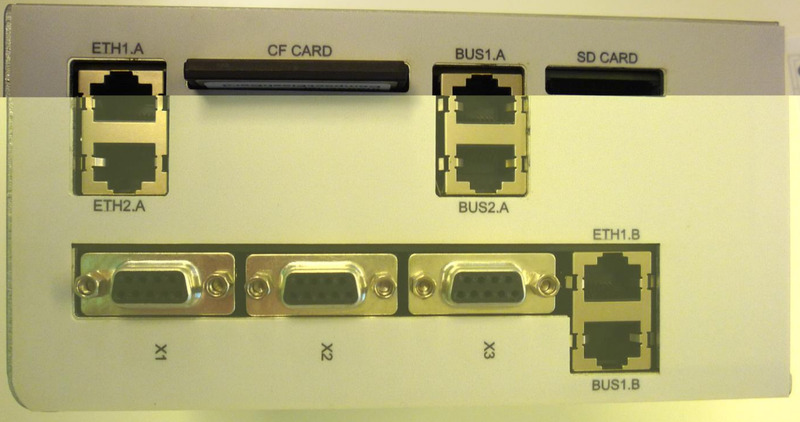

Top side

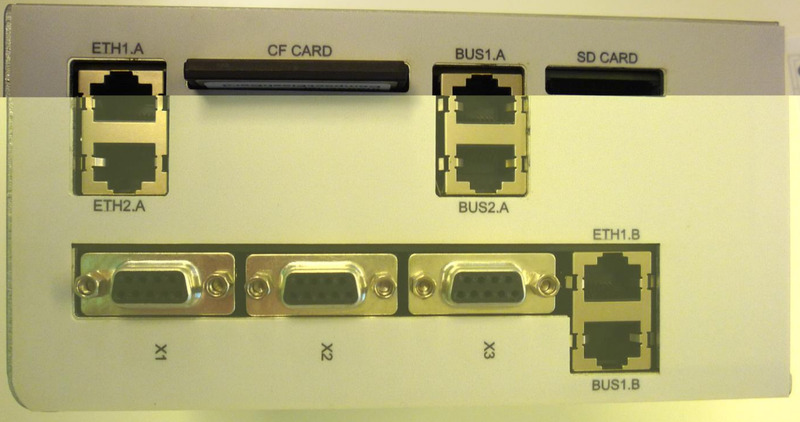

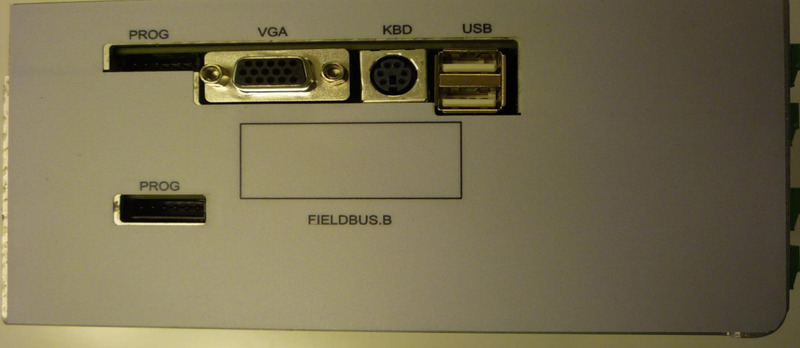

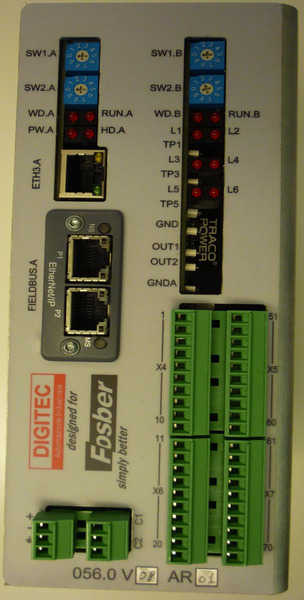

Front side

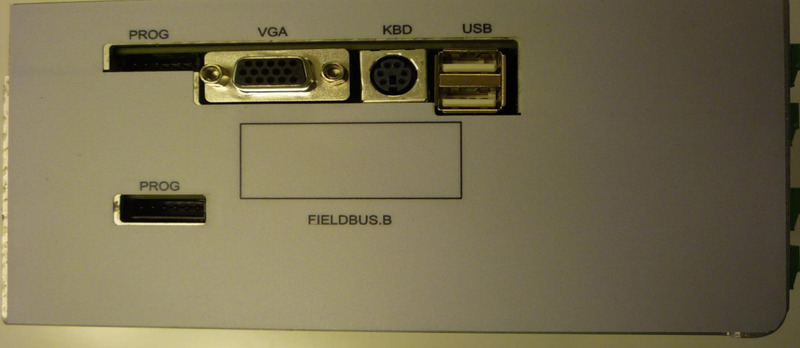

Lower side

- PROG : Programming micro (reserved for DIGITEC use)

- VGA : Video PC104 (reserved for DIGITEC use)

- KBD : Keyboard PC104 (reserved for DIGITEC use)

- USB : Usb PC104 (reserved for DIGITEC use)

- PROG : Programming micro (reserved for DIGITEC use)

- FIELDBUS.B: Slot for ANYBUS CC M40

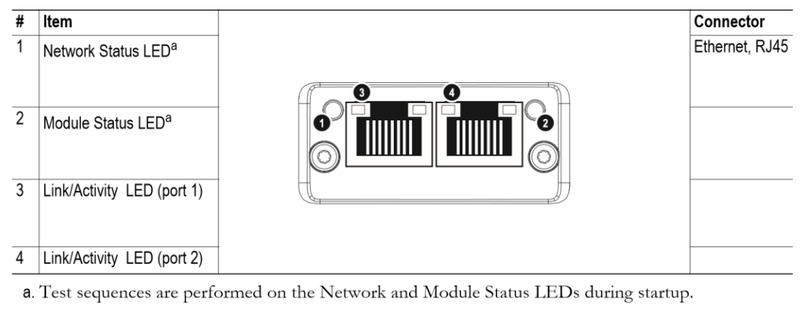

3. Fielbus ANYBUS CC M40

The cutting system provides the possibility to mount a field bus to interface to the various market PLC type

SIEMENS – ALLEN BRADLEY ...

The Fieldbus used in addition to being marked in ANYBUS module is coded with VXX code. To check module diagnostics, refer to the module version :

- V01 : Card without fieldbus.

- V08 : ETHERNET IP

- V09 : PROFINET

4. Fosber Master 400 Configuration (software version 100)

SW2.B: Line in run configuration level

- -switch 1: -ETHERNET/IP 192.168.1.16 (level 1) -PLC 056.0 192.168.1.15

- -switch 2: -ETHERNET/IP 192.168.1.26 (level 2) -PLC 056.0 192.168.1.25

- -switch 3: -ETHERNET/IP 192.168.1.36 (level 3) -PLC 056.0 192.168.1.35

- -switch 4: -ETHERNET/IP 192.168.1.82 (L1 Cina) -PLC 056.0 192.168.1.102

- -switch 5: -ETHERNET/IP 192.168.1.83 (L2 Cina) -PLC 056.0 192.168.1.104

L1 TP1: Material presence photocell (X4.1/2)

Photocell ON (TP1 ON) = Led off

Fhotocell OFF (TP1 OFF)= Led off

L2: Not used

L3 TP3: Loading sensor on syncro zone zero position

L4: Syncro Zone

Syncro Zone on = Led off

L5 TP5: Cut to mark photocell filtered input (X4.5/6)

Photocell ON (TP5 ON) = Led off

Photocell OFF (TP5 OFF)= Led off

L6: OK Pattern recognized = Led off

OUT 1: Speed reference

OUT 2: Speed rotation (ENCODER X3)

ETH1.A: Network ETHERCAT for drive

FIELBUS.A: Network ETHERNET/IP for PLC connection

X1: Measuring wheel encoder input

X2: Pull-Roll encoder input

X3: Motor rotation input

X4.1/2: Presence material photocell

X4.2/3: Loading sensor input

X4.5/6: Cut to mark photocell input

X4.7/8: Tracking scrap splice input

X5.52: Cut error signal (out of range)

X5.53: Waste flat opening and closing

X5.55: Cut signal

X5.56: Up/down no crash roll

X5.57: Pressure exchange no crash roll

X7.61/62: Drive torque reference output

X7.63/64: Drive torque reference output

X7.68/69/70: Cut rack supply |